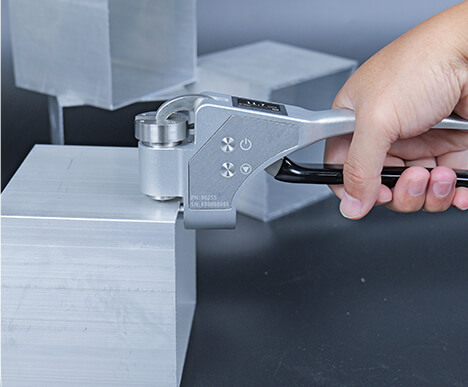

86255 Webster Hardness Tester

Digital Display | Simple Operation | Accurate Measurement

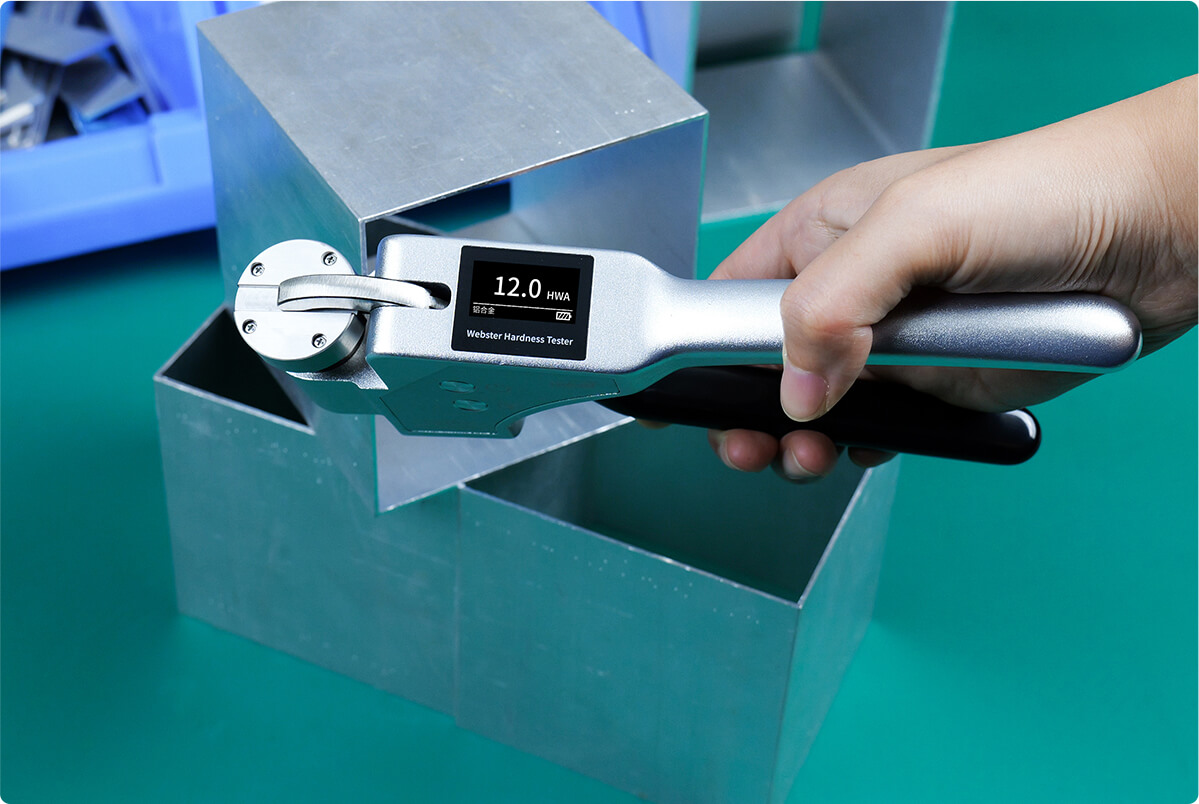

Easy-to-read digital display with 0.1 HWA high resolution

Automatic data locking for quick and convenient readings

Multiple hardness scales with seamless switching—no more manual lookups

Calibration without disassembly—fast, user-friendly, and precise

High measurement accuracy, certified by authoritative metrology institutions

The 86255 Webster Hardness Tester is based on the Webster hardness testing principle, ideal for measuring the hardness of aluminum alloys, brass, copper, mild steel, and other metal materials. It's especially suited for quick, non-destructive, and individual piece qualification testing of metal profiles, sheets, and tubes in production lines, sales environments, and on construction sites.

Utilizing eddy current induction technology, this tester ensures excellent repeatability and measurement precision. It supports multiple hardness measurement systems including Webster (HWA), Rockwell (HRE, HRF, HRB), Vickers (HV), and Brinell (HB), with easy on-device conversion.

Application

Parameters

| Parameter | Value |

|---|---|

| Hardness Scales | HWA、HRE、HRF、HRB、HV、HB |

| Measurement Range | HWA(0-20); HRE(23.5-110); HRF(26.2-105.5); HRB(0-85.3); HV(49-155); HB(35.2-153) |

| Resolution | 0.1HWA |

| Accuracy | ±0.5HWA |

| Repeatability | 0.5HWA |

| Thickness Of Measured Material | 0.6mm-8mm |

| Inner Diameter Of The Measured Material | >10mm |

| Display | 128 * 64 dot matrix OLED |

| Power Supply | Rechargeable lithium battery 3.7V@400mAh, full charge for over 5000 continuous measurements |

| Charging Port | USB(Type-C) |

| Size | 203*97*30 mm |

| Weight | 484g |

| Supply Voltage | DC5V |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Digital display

Equipped with an OLED screen positioned at the top of the device, the display offers clear readability and eliminates errors caused by analog dial interpretation.

Automatic Data Locking

The auto-lock feature allows you to obtain readings without fully pressing the handle—making operation quicker and more efficient.

Multiple Hardness Scales

Easily switch between six built-in hardness scales: Webster (HWA), Rockwell (HRE, HRF, HRB), Vickers (HV), and Brinell (HB). No need for manual comparison tables.

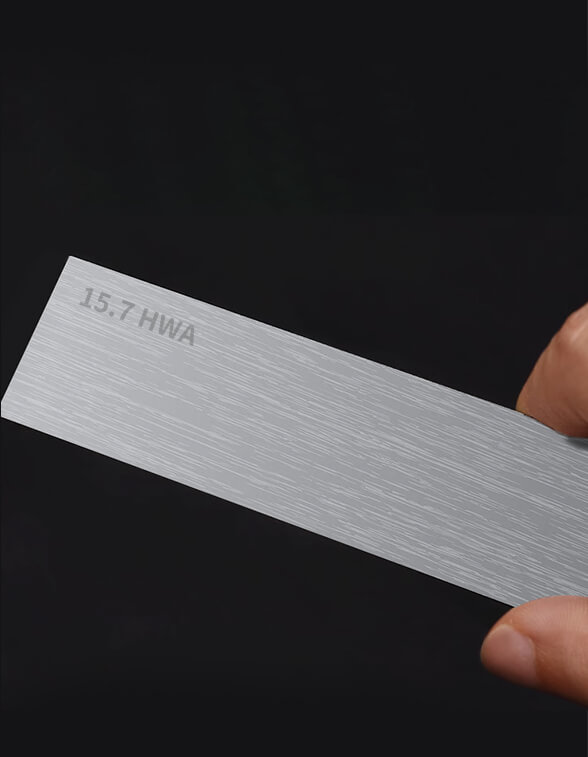

Tool-Free Calibration

The device supports direct reference and hardness calibration without disassembly. Calibration can be done quickly using a standard block, simplifying the process compared to traditional Webster testers.

High Accuracy & Repeatability

With an accuracy of ±0.5 HWA and repeatability of up to 0.5 HWA, the device meets strict metrology standards and delivers consistent results.

Stores Up to 9 Readings

The built-in memory can store up to 9 sets of data, allowing users to perform multiple tests and track results with ease.

High 0.1 HWA Resolution

Thanks to the eddy current induction technology, the device achieves a resolution of 0.1 HWA, offering precise and reliable measurements.

Mobile App Integration

A dedicated mobile app enables remote testing, mass data storage, result export, and sharing—making it ideal for digital workflows.

All-in-One Handheld Device

Designed for portability and ease of use, this lightweight tool can be operated with one hand—perfect for quick hardness verification on-site.

Ergonomic Build

Crafted from forged aluminum alloy with anodized finishing, the tester offers a comfortable grip and excellent resistance to wear and contaminants.

Standard Hardness Block Included

Comes with a certified Rockwell hardness block that meets strict surface roughness and flatness specifications for reliable calibration.

Durable High-Hardness Indenter

Made from premium materials, the indenter features excellent toughness and long-lasting performance.

Rechargeable lithium battery with ultra-low power consumption

Built-in buzzer for clear operation feedback

Automatic peak value locking during measurement

Qualifications and Standards

Standards for the product:

GB/T 32660.1-2016 Metallic materials -Webster hardness test - Part 1: Test method

GB/T 32660.2-2016 Metallic materials - Webster hardness test - Part 2: Verification and calibration of hardness testers

GB/T 32660.3-2016 Metallic materials - Webster hardness test - Part 3: Calibration of reference blocks

GB/T 33362-2016 Metallic materials - Conversion of hardness values

JJG 944-2013 Metallic Webster Hardness Testing Machines

Packing List

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Webster Hardness Tester | 1 | Set |

| 2 | USB Data Cable | 1 | pcs |

| 3 | Standard hardness block | 1 | pcs |

| 4 | User Manual | 1 | pcs |

| 5 | Calibration Report | 1 | pcs |

| 6 | Certificate / Warranty Card | 1 | pcs |

Software Download

APP supports Android operating system version 7.0 or higher.

It can be installed by:

1) Use your mobile browser to scan the QR code on the instrument, follow the prompts to download and install.

2) Search for "UT and HL" (case insensitive) in the Google Play to install the application