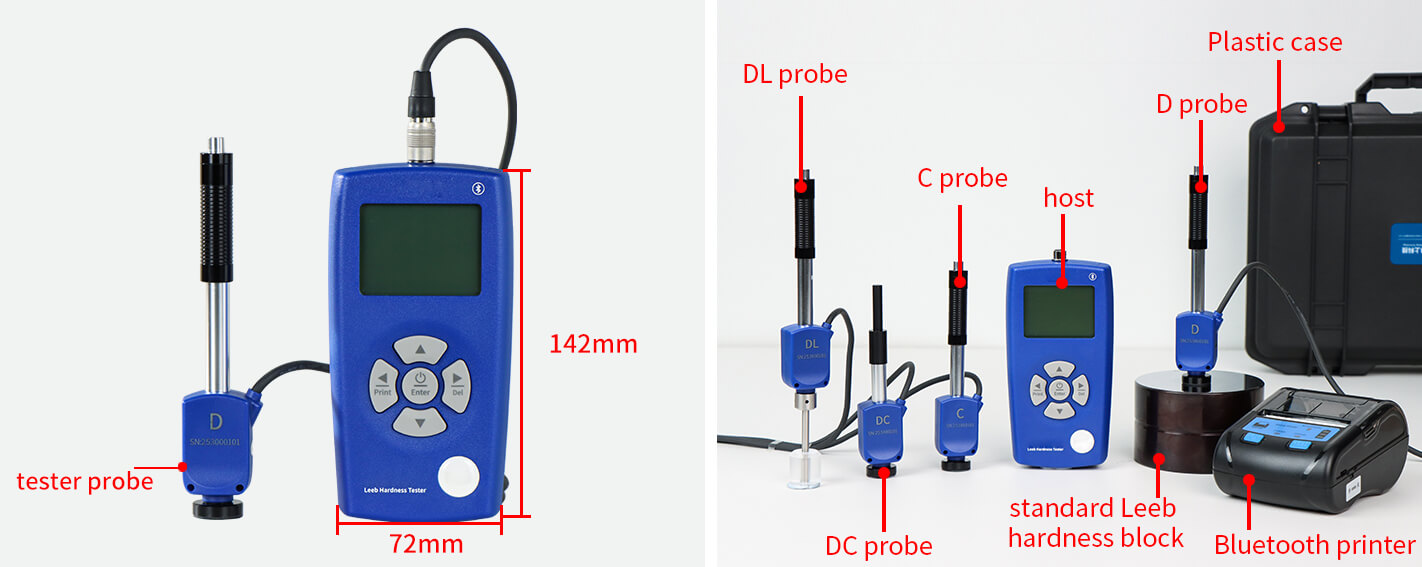

86253 Multi-probe Leeb Hardness Tester

Compatible with four types of impact devices: D, DL, DC, and C

Optional Bluetooth wireless printer for instant result printing

Dual-coil digital probe for precise and stable measurements

Automatic conversion between multiple hardness scales—no manual lookup required

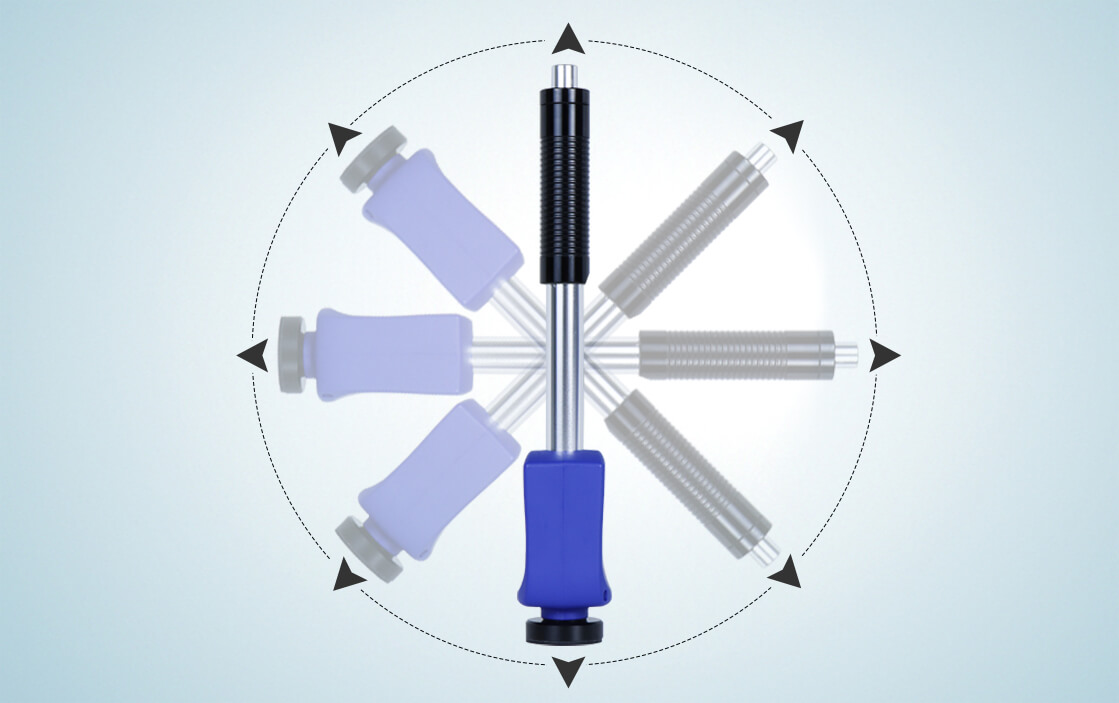

Built-in orientation sensor with 360° impact compensation

The 86253 is a split-type Leeb hardness tester with a host unit and probe connected via aviation-grade plugs. The host automatically detects the type of impact device in use. It features an advanced digital dual-coil probe that delivers highly accurate and interference-resistant measurements. The tester supports various hardness scales, including Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), and Rockwell (HRA/HRB/HRC), with automatic conversion between them—eliminating the need for manual calculation. In addition to hardness, it can also measure material strength. The unit is compatible with four different types of impact devices (D, DC, DL, and C) to meet different testing scenarios.

Application

The 86253 Leeb hardness tester is suitable for a wide range of materials, including steel, cast steel, alloy steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy, copper-tin alloy, pure copper, and forged steel. It is ideal for applications such as machine tool guides, automotive chassis, large workpieces, mold cavities, bearings, pressure vessels, and assembled machinery parts. This makes it an excellent tool for manufacturers conducting product quality control and process optimization.

Impact device selection

| No | Impact type | Application |

|---|---|---|

| 1 | D | Ordinary metal parts |

| 2 | DC | Short size, suitable for internal holes or narrow areas |

| 3 | DL | Slender narrow groove, tooth flank or bottom of bore |

| 4 | C | Hardfacing and small or thin components |

Parameters

| Parameter | Value |

|---|---|

| Probe | Impact device D/ Impact device DC / Impact device DL/ Impact device C |

| Hardness Scales | HL, HV, HB, HS, HRA, HRB, HRC |

| Measurement Range | Impact device D/DC:HLD: (170-960); HV(83-976); HB(30-651); HRC(17.6-68.5); HS(26.4-99.5); HRB(13.5-100); HRA(60-85.8) Impact device DL:HLDL(170-960); HV(194-976); HB(140-651); HRC(19.8-68.5); HS(26.4-99.5); HRB(59.6-99.6); HRA(60-85.5) Impact device C:HLC(170-960); HV(80-996); HB(80-683); HRC(20-69.5); HS(31.9-102.3) |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL (typical) |

| Repeatability | 6HL (factory standard) |

| Display | 240 * 16 dot matrix LCD |

| Power Supply | 2 AA alkaline dry batteries |

| Host Size | 142*72*28 mm |

| Probe Size | 148*31*25 mm |

| Weight | 247g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Compatible with Four Impact Devices

The host unit connects with up to four interchangeable impact devices via aviation-grade plugs, offering flexibility across various testing needs.

Bluetooth App Support

Easily connect the device to a mobile app via Bluetooth for data storage and sharing. Multiple measurement sets can be saved and managed directly from your phone.

Dual-Coil Technology for High Accuracy

The advanced dual-coil design ensures high measurement precision and excellent repeatability, ideal for demanding quality inspections.

360° Directional Compensation

A built-in direction sensor in the probe allows for full-circle impact detection and automatic compensation, ensuring consistent results regardless of testing angle.

Multiple Hardness Scale Conversions

Easily switch between different hardness standards—Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), and Rockwell (HRA/HRB/HRC)—without the need for manual reference tables.

Certified High Precision

With a measurement accuracy of up to ±6 HL, the 86253D meets the stringent standards of China's national metrology authority.

Optional Bluetooth Thermal Printer

Print your test results instantly by pairing the device with a Bluetooth-enabled thermal printer.

Two Measurement Modes

Choose between QC mode and statistical mode to match your testing requirements. The tester automatically calculates the maximum, minimum, and average values from the last nine measurements. It also allows users to set upper and lower thresholds for quick batch quality checks.

Qualifications and Standards

86253 Leeb Hardness Tester conforms to the following standards:

GB/T 17394.1 Metallic materials-Leeb hardness test-Part 1: Test method

GB/T 17394.2 Metallic materials-Leeb hardness test-Part 2: Verification and calibration of hardness tester

GB/T 17394.4 Metallic materials-Leeb hardness test-Part 4:Tables of hardness values conversion

JB/T 9378-2001 Industry standard of Leeb hardness tester

JJG 747-1999 Verification regulation of Leeb hardness tester

Packaging

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Leeb Hardness Tester Host | 1 | Set |

| 2 | Leeb Hardness Tester Probe | According to the numbers of probe ordered | |

| 3 | Bluetooth Printer | According to the numbers of printer ordered | |

| 4 | Standard Leeb hardness Bblock | 1 | pcs |

| 5 | Nylon Brush | 1 | pcs |

| 6 | Small Support Ring | 1 | pcs |

| 7 | User Manual | 1 | pcs |

| 8 | Calibration Report | 1 | pcs |

| 9 | Certificate / Warranty Card | 1 | pcs |

| 10 | Plastic Case | 1 | pcs |

Precaution

The Leeb hardness tester is only suitable for large, heavy workpieces. Small, thin workpieces should be coupled to a firm support for testing.

| Impact device type | Minimum mass | Minimum thickness (uncoupled) | Minimum thickness (coupling) |

|---|---|---|---|

| D、DL、DC | 5kg | 25mm | 3mm |

| C | 1.5kg | 10mm | 1mm |

Software Download

APP supports Android operating system version 7.0 or higher.

It can be installed by:

1) Use your mobile browser or WeChat to scan the QR code on the instrument, follow the prompts to download and install.

2) Search for "UT and HL" (case insensitive) in the Google Play to install the application.