86252C Leeb Hardness Tester

Optimized for testing surface-hardened layers and components with low mass or thin profiles

Utilizes Impact Device C

Features dual-coil technology for superior accuracy and repeatability

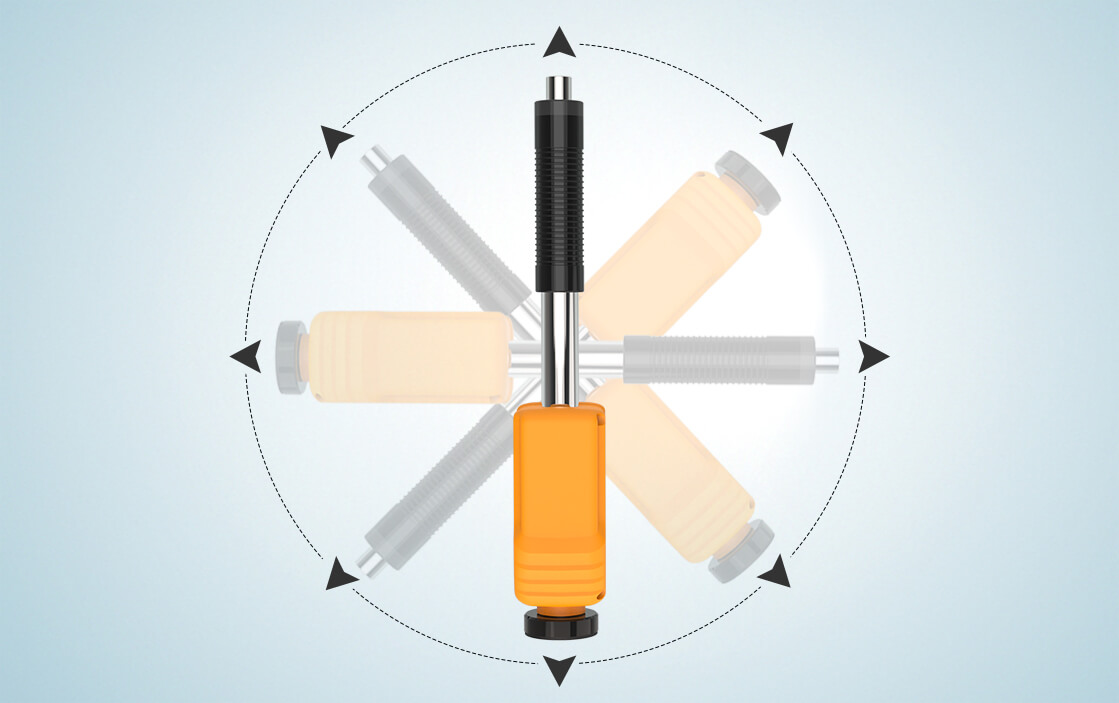

Built-in orientation sensor enables full-angle measurement

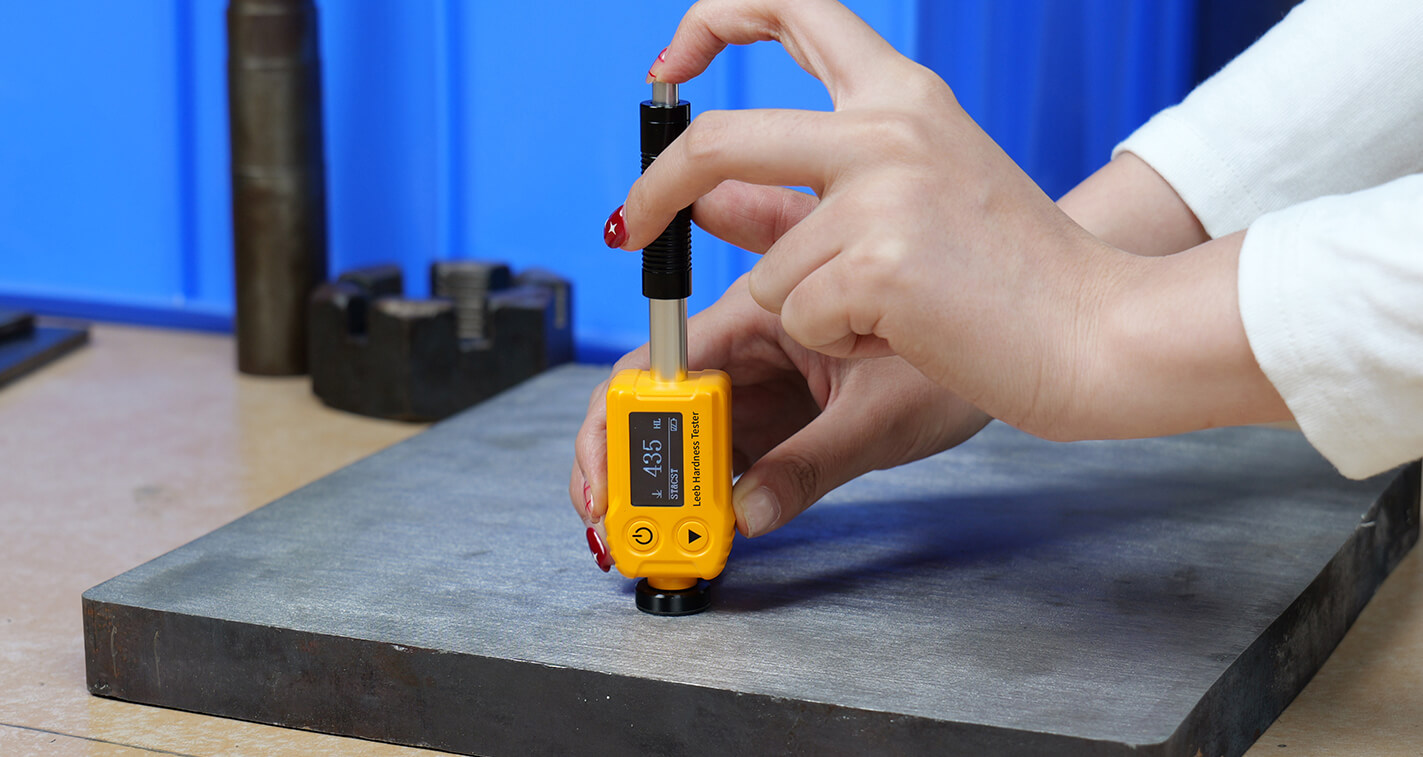

The 86252C is a compact, all-in-one hardness tester designed for accurate measurements on a wide range of metal materials. It features a C-type impact device with low impact force, making it ideal for assessing the hardness of surface-hardened layers and small or thin components. Advanced dual-coil technology ensures high measurement precision and consistency. The integrated orientation sensor in the probe automatically adjusts for different testing angles, providing reliable results regardless of direction. The tester supports five interchangeable hardness scales—Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), and Rockwell (HRC)—removing the need for manual conversions.

Application

Equipped with an Impact Device C, the 86252C supports a variety of metal materials, making it suitable for a broad range of industrial and maintenance applications.

Parameters

| Parameter | Value |

|---|---|

| Probe | Impact device C |

| Hardness Scales | HL, HV, HB, HS, HRC |

| Measurement Range | HLC: (170-960); HV(80-996); HB(80-683); HRC(20-69.5); HS(31.9-102.3); |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL typical |

| Repeatability | 6HL (factory standard) |

| Display | 128 * 64 dot matrix OLED |

| Power Supply | Rechargeable lithium battery 3.7V@250mAh, full charge for over 5000 continuous measurements |

| Charging Port | USB(Type-C) |

| Size | 140*34*24 mm |

| Weight | 66g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Impact Device C for Small or Thin Metal Parts

The low-force Impact Device C is tailored for testing small, lightweight, or thin-walled metal components, as well as surface-hardened layers.

Compact, All-in-One Design

Weighing only 66 grams, this lightweight tester is easy to carry and ideal for use in the field or on production lines.

High Accuracy with Patented Dual-Coil Technology

The state-of-the-art dual-coil system delivers high measurement accuracy and excellent repeatability, ensuring consistent test results.

Built-In Orientation Sensor for Multi-Angle Testing

The internal direction sensor compensates automatically for variations in impact angle, allowing for precise readings from any direction.

Wide Compatibility with Metal Materials

With 10 pre-set metal options—including steel, alloy tool steel, stainless steel, and gray cast iron—the 86252C is adaptable to a variety of testing scenarios and industries.

Multiple Hardness Scale Conversions

Easily switch between five common hardness scales: Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), and Rockwell (HRC), eliminating the need for manual reference tables.

Durable Tungsten Carbide Impact Tip

Partially constructed with tungsten carbide, the impact device offers exceptional wear resistance, with a hardness level close to that of diamond.

Certified Testing Accuracy

Tested and approved by the National Institute of Metrology, ensuring compliance with recognized accuracy standards.

USB Rechargeable Battery

Powered by a rechargeable lithium battery, the device can be easily recharged via USB, offering a convenient power solution.

Long Battery Life with Smart Power Management

Thanks to a dynamic hibernation algorithm and large-capacity battery, the 86252C provides up to 35 hours of continuous operation on a full charge.

User Calibration Capability

Users can perform recalibration using standard reference parts to maintain accuracy and account for environmental or material variations.

Qualifications and Standards

The hardness tester conforms to the following standards:

GB/T 17394.1 Metallic materials-Leeb hardness test-Part 1: Test method

GB/T 17394.2 Metallic materials-Leeb hardness test-Part 2: Verification and calibration of hardness tester

GB/T 17394.4 Metallic materials-Leeb hardness test-Part 4: Tables of hardness values conversion

JB/T 9378-2001 Industry standard of Leeb hardness tester

JJG 747-1999 Verification regulation of Leeb hardness tester

Packing

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Leeb Hardness Tester | 1 | Set |

| 2 | USB Data Cable | 1 | pcs |

| 3 | Nylon Brush | 1 | pcs |

| 4 | Small support Ring | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Calibration Report | 1 | pcs |

| 7 | Certificate / Warranty Card | 1 | pcs |

FAQ

-

What is the thinnest thickness a durometer can measure and what is the thinnest thickness after coupling?

Leeb hardness tester is only suitable for large and heavy workpieces, small and thin parts must be coupled to a solid support for testing; D-type impact device is measured by the minimum mass of 5kg, the minimum thickness of 25mm, if the weight or thickness does not meet the requirements, must be coupled to a solid support for testing, coupled to the minimum thickness of the measured object is 3mm.