86236 Car Paint Meter

The enemy of metallic putty

OLED screen resistant to extreme cold

Accurately identifies galvanized steel body panels

The 86236 paint film gauge is a professional tool designed for measuring automotive paint thickness. It features the classic capability of automatically distinguishing between steel, aluminum, and plastic substrates. Additionally, the 86236 is equipped with an advanced intelligent detection algorithm that can identify accident repairs involving metallic putty, as well as automatically recognize high-grade galvanized steel bodies with anti-corrosion coatings. With both a high-definition LCD display and an ultra-low temperature OLED screen, the device functions reliably even under intense sunlight or in temperatures as low as –40°C. The dual-screen design ensures clear readings from any angle while inspecting a vehicle.

Parameters

| Parameter | Coating Thickness Gauge |

|---|---|

| Probe Tip | Ruby |

| Measuring Principle | Fe: Hall Effect / NFe: Eddy current |

| Probe Type | Built-in integrated probe |

| Measuring Range | 0.0-5000μm |

| Resolution | 0.1μm/1μm/10μm |

| Accuracy | 0-3000μm: ≤±(3%H+2μm), H is the standard value 3000-5000μm: ≤±(5%H+2μm), H is the standard value |

| Unit | μm / mil |

| Measuring Interval | 0.5s |

| Minimum Measuring Area | Ø = 25mm |

| Minimum Curvature | Convex:5mm / Concave:25mm |

| Minimum Substrate Thickness | Fe:0.2mm / NFe:0.05mm |

| Language | 中文、English、Русский、Türkçe |

| Display | Front: 128×48 dot matrix LCD, top: 128×64 dot matrix OLED |

| Power Supply | 2 pcs of 1.5V AAA alkaline battery |

| Operation Temperature Range | -40℃-50℃ |

| Storage Temperature Range | -50℃-60℃ |

| Gauge Size | 100*60*24 mm |

| Weight(with battery) | 80g |

Features

Quickly detect metallic putty repairs

If a vehicle's body has been repaired using metallic putty, the paint meter will detect it in automatic mode. A buzzer will sound, and a red light will indicate the presence of putty.

Integrated app with test report generation

With Bluetooth data transmission, the device connects seamlessly to a smartphone app. Measurement data can be used to generate detailed test reports, which can be saved or shared easily.

Automatic recognition of galvanized steel body panels

In automatic mode, the meter can detect galvanized steel bodywork. This helps determine if original factory panels have been replaced. When galvanized steel is identified, the screen displays a green backlight.

Versatile functions for practical use

The automotive paint meter offers multiple features and powerful performance, quickly identifying steel, aluminum, and non-metal materials on vehicles.

The car paint meter tests ferrous car body

The car paint meter tests aluminum car body

The car paint meter tests non-metal material

High-definition and cold-resistant screens for extreme environments

The combination of a high-definition LCD screen and a low-temperature-resistant OLED screen ensures reliable operation in harsh conditions. The LCD remains clear under strong light, while the OLED functions properly at –40°C.

Dual-screen design for easy reading

The meter features both front and top displays, allowing users to read measurements comfortably from any angle during full-vehicle inspections.

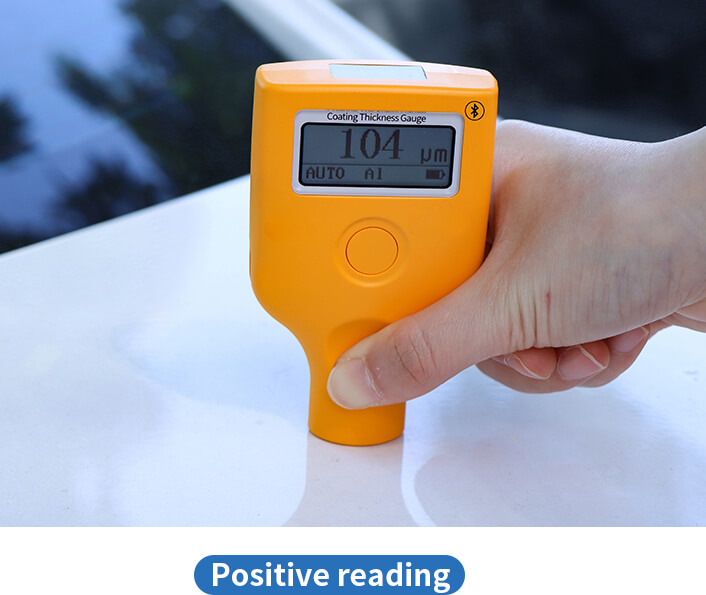

Front screen reading

Top screen reading

Fast response and short measuring intervals

The device delivers quick results, completing each measurement in just 0.5 seconds.

Durable ruby probe for long-term accuracy

The wear-resistant ruby probe minimizes inspection errors caused by wear and extends the lifespan of the meter.

Advanced digital probe for precise measurements

Thanks to advanced digital probe technology, data is processed directly at the probe, minimizing interference and ensuring excellent accuracy, consistency, and data stability throughout the measurement process.

Material recognition with three backlight colors

Red, green, and white backlights indicate different materials detected:

– Bright red signals metallic putty

– Bright green indicates galvanized steel

– Bright white represents other materials

Screen turns white under normal measurement conditions

Screen turns green when recognizing iron galvanized car body

Screen turns red when recognizing ferrous putty

Three selectable measurement modes

No calibration required—simple zero adjustment for easy use

Four language display options for international accessibility

Units can be switched freely

Qualifications and Standards

Standards for the product:

DIN EN ISO 2808 Paints and Varnishes-Determination of Film Thickness

JJG-818-2005 Verification Regulation of Magnetic and Eddy Current Measuring Instrument for Coating Thickness

GB/T 4956-2003 Non-magnetic Coatings on Magnetic Substrates-Measurement of Coating Thickness-Magnetic Method

GB/T 4957-2003 Non-conductive Coatings on Non-magnetic Basis Metals-Measurement of Coating Thickness-Eddy Current

App Installation

Coating Thickness Gauge APP is compatible with iOS 12.0 and later, as well as Android OS 6.0 and later. Scan the QR code below with Google Play to download and install the CoatingThicknessGauge.apk program. Following installation, the "Coating Thickness Gauge" icon will appear on your phone's desktop, as seen below.

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | Coating Thickness Gauge | 1 | Set |

| 2 | Fe Zero-adjustment Plate | 1 | pcs |

| 3 | NFe Zero-adjustment Plate | 1 | pcs |

| 4 | Standard Film | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Certificate / Warranty Card | 1 | pcs |

FAQ

-

1. How to judge whether the car has been repainted or not?

At present, the paint thickness of different brands of cars on the market is not exactly the same. Therefore, when measuring the paint film thickness of a certain car, you can first measure the paint thickness on the car roof, because car roof is rarely affected by external forces and scratches, dents or deformation, it is more likely to retain the original paint thickness. To test the specfic position of the car, you can take the upper, lower, left, right, and middle five points to test and calculate the average value of the five data. If the value of one point is greater than the average value of more than 30μm, this position may have been repainted.

-

2.Under what circumstances we need to make zero adjustment?

When the body material of the car under test changes; the instrument has not been used for a long time; when the ambient temperature changed significantly; after the battery is replaced; when it can not recognize ferrou putty or iron galvanized cae body.

-

3.Can I customize the LOGO and shell of the car paint meter?

Yes, but there is a minimum order quantity. The minimum order quantity for customized LOGO: 100pcs; the minimum order quantity for customized instrument shell: 500pcs.