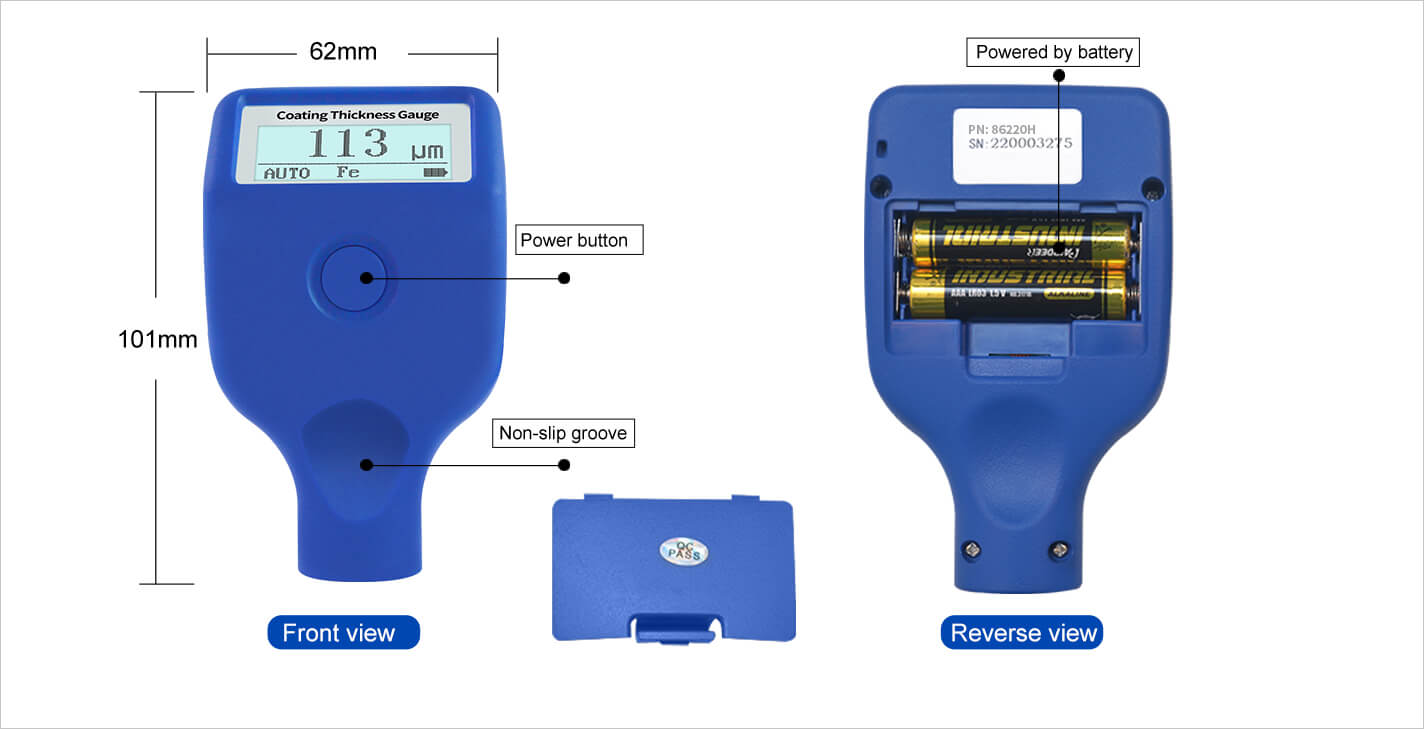

86220H Dry Film Thickness Gauge

High accuracy and good stability

Measure coating on ferrous/non-ferrous substrates

Dry film thickness measurement range: 0-2000μm

86220H is an integrated high-precision coating thickness gauge, which combines the Hall effect and Eddy current thickness measurement principles. Based on the Hall effect, the instrument can measure non-ferromagnetic coatings on ferromagnetic metal substrates, while under the Eddy current principle effect, it can measure non-conductive coatings on non-magnetic metal substrates.

- There are only four types of ferromagnetic metal elements at room temperature: iron, cobalt, nickel, and gadolinium.

- Common non-ferromagnetic metals: copper, aluminum, zinc, chromium, etc.

- Hall effect: can be used for the measurement of non-ferromagnetic coatings on ferromagnetic metal substrates.

- Eddy current: can be used for the measurement of non-conductive coatings on non-magnetic metal substrates.

| Substrate | Coating | Examples | Yes/No |

|---|---|---|---|

| Ferromagnetic Materials: Iron, Cobalt, Nickel, Gadolinium |

Non-ferromagnetic metal | 1. Galvanized iron copper plating | √ |

| Non-metal materials | 1. Iron spray paint 2. Iron spray powder coating |

√ | |

| Ferromagnetic material: Iron, cobalt, nickel and gadolinium | Iron nickel plating | × | |

| Non-ferromagnetic Metal: Copper, Aluminum, Magnesium, Zinc, Etc. |

Non-conductive material | 1. Anodized ; aluminum surface 2. copper, spray paint |

√ |

Application

86220H Coating Thickness Gauge tests the coatings on shelves

86220H Coating Thickness Gauge tests the coatings on ferrous material

86220H Coating Thickness Gauge tests the coatings on aluminum frame

86220H Coating Thickness Gauge tests the coatings on aluminum window sill

Parameters

| Parameter | Value |

|---|---|

| Probe Tip | Ruby fixed |

| Measuring Principle | Ferrous: Hall Effect / Non-ferrous: Eddy current |

| ProbeType | Integrated probe |

| Measuring Range | 0.0-5000μm |

| Resolution | 0.1μm: 0μm - 99.9μm 1μm: 100μm - 999μm 0.01mm: 1.00mm - 2.00mm |

| Accuracy | ≤±(3% reading+2μm) |

| Unit | μm / mil |

| Measuring Interval | 0.5s |

| Minimum Measuring Area | Ø = 25mm |

| Minimum curvature | Convex:5mm / Concave:25mm |

| Minimum Substrate Thickness | Fe:0.2mm / NFe:0.05mm |

| Display | 128×48 dot matrix LCD |

| Power Supply | 2pcs of 1.5V AAA alkaline battery |

| Operation Temperature Range | 0℃-50℃ |

| Storage Remperature Range | -20℃-60℃ |

| Gauge Size | 101*62*28 mm |

| Weight(with battery) | 79 g |

Features

Powerful and dual-use for ferrous and non-ferrous substrate

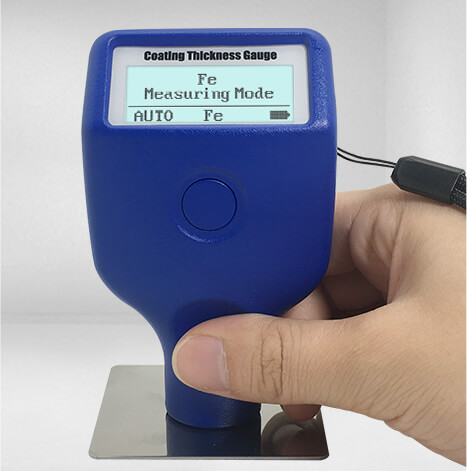

Dual-use probe for both iron and aluminum. The dry film thickness gauge has intelligent identification of measurement substrate and fast automatic transfer.

86220H can identify non-metal substrate

86220H can identify ferrous substrate

86220H can identify non-ferrous substrate

Available in three different modes

The 86220H coating thickness gauge has three measurement modes:Fe mode, NFe mode and Fe/NFe mode.

Small, Lightweight and Portable

The 86220H dry film thickness gauge has simple design and small size. It is easy to carry and operate.

High-quality digital probe ensures accurate measurement and stable data

The advanced digital probe is used to keep the zero position stable for a long time without drifting. The test data is stable after testing the same position for multiple times.

Robust and durable

Ruby probe with abrasion and corrosion resistance to ensure long service life. Avoids errors caused by wear.

With temperature compensation technology, the gauge can be used at minus 20 degrees Celsius

Suitable for testing coatings on ultra-thin substrates

Available in English and Chinese

Qualifications and Standards

86220H dry film thickness gauge conforms to the following standards:

GB/T 4956-2003 Non-magnetic Coatings on Magnetic Substrates-Measurement of Coating Thickness-Magnetic Method

GB/T 4957-2003 Non-conductive Coatings on Non-magnetic Basis Metals-Measurement of Coating Thickness-Eddy Current

DIN EN ISO 2808 Paints and Varnishes-Determination of Film Thickness

JJG-818-2005 Verification Regulation of Magnetic and Eddy Current Measuring Instrument for Coating Thickness

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | 86220H Coating Thickness Gauge | 1 | Set |

| 2 | Fe Zero-adjustment Plate | 1 | pcs |

| 3 | NFe Zero-Adjustment Plate | 1 | pcs |

| 4 | Standard Film | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Certificate / Warranty Card | 1 | pcs |

FAQ

-

1. The difference between 86220H and 86221

The functions and parameters of 86220H and 86221 are exactly the same, but the 86220H coating thickness gauge adopts an integrated design and can be operated with one hand; while the 86221 adopts a split design, the probe size is smaller, which is suitable for measuring narrow spaces and some special positions.