86213 Ultrasonic Thickness Gauge

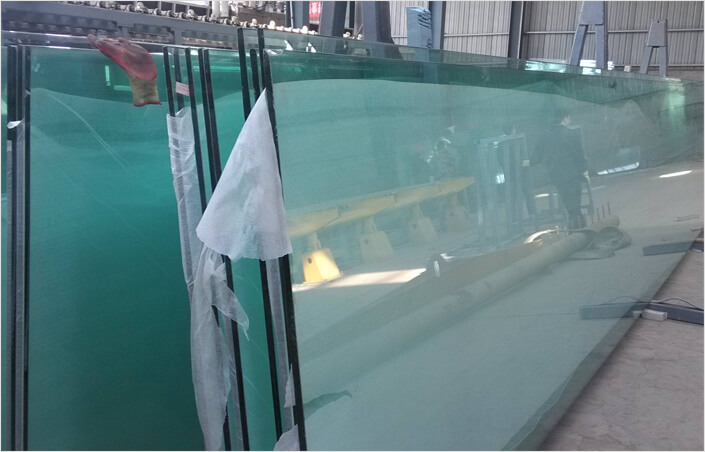

Non-destructive testing for metals, glass, ceramics, and plastics

The 86213 precision ultrasonic thickness gauge delivers fast, accurate measurements.

It features two measurement modes: QC Mode and Statistics Mode, a high-sensitivity dual-crystal probe, and switchable automatic gain.

The 86213 ultrasonic thickness gauge is user-friendly and operates on the principle of ultrasonic pulse reflection to measure material thickness. It is compatible with four probe types—standard, micro-diameter, coarse crystal, and high-temperature probes—and is ideal for measuring the thickness of metals (like steel, aluminum, copper), plastics, ceramics, glass, fiberglass, and other ultrasonic-conductive materials.With a dedicated timing chip, it offers a resolution of up to 0.01 mm.

Video

How to use the ultrasonic thickness gauge

Application

In many industries, It is essential to measure the wall thickness to confirm the condition of the material for the normal running of the items or structure safety.86213 ultrasonic thickness gauge can be widely used in testing the thickness of various accessories or metallic structure to check them whether to be repaired or changed such as ships, tanks, pipes or steel structure. The gauge is applicable for petroleum, chemical, metallurgical, shipbuilding, aviation and aerospace various fields.

Parameters

1. Probe specifications and parameters

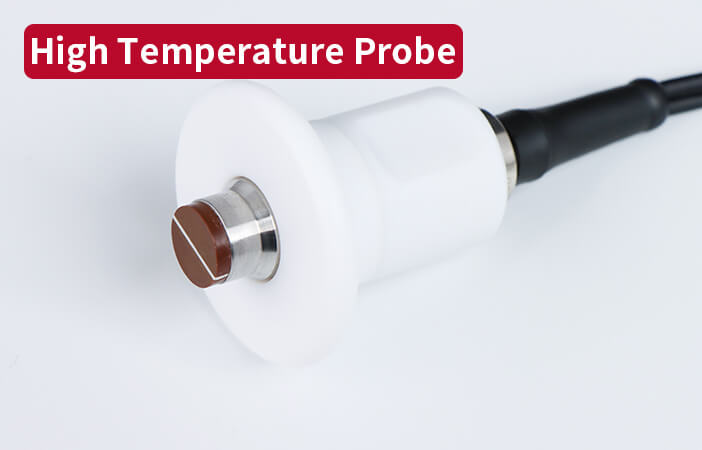

| Probe | Standard Probe | Micro-diameter Probe | Coarse Crystal Probe | High Temperature Probe |

|---|---|---|---|---|

| Probe Model | 5MHZφ10 | 7MHZ PT-06 | 2MHZ ZT-12 | 5MHZ GT-12 |

| Minimum Measuring Aarea | φ10mm | φ6mm | φ12mm | φ12mm |

| Probe Size | φ18*26mm | φ15*25mm | φ18*28mm | φ43*48mm |

| Measuring Range(45#steel) | 0.8-350mm | 0.75-80mm | 3-200mm | 3-200mm |

| Accuracy(H is the standard value) | H<10mm:±0.05mmH≥10mm:±0.5%H | H<10mm:±0.05mmH≥10mm:±0.5%H | H<10mm:±0.1mmH≥10mm:±0.5%H | H<10mm:±0.05mmH≥10mm:±0.5%H |

| Pipe Measurement Lower limit(45# steel) | φ20*3mm | φ20*2mm | φ30*4mm | φ30*4mm |

| Exposure Temperature | -10~60℃ | -10~60℃ | -10~60℃ | -10~500℃ |

| Application | Measure conventional workpieces | Measure surfaces and small workpieces | Cast iron and some materials with large crystal particles | Measure high temperature workpieces |

2. Host parameters

| Parameters | Values |

|---|---|

| Measuring Range | 0.8-350mm(45#steel) |

| Resolution | 0.8-100mm:0.01mm 100-350mm:0.1mm |

| Accuracy | 0.8-10mm:±0.05mm 10-350mm:±0.5% |

| Sound Velocity Range | 1000~19999m/s |

| Probe Specification | 5MHz φ10 dual-crystal probe |

| Display | 240 * 160 dot matrix LCD |

| Unit | mm/inch |

| Power Supply | 2 * AA alkaline dry batteries |

| Host Size | 142 * 72 * 28 mm |

| Weight | about 230g |

| Working Temperature Range | -10~50℃,0~85%RH(No condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(No condensation) |

Features

High-sensitivity dual-crystal probe

The probe uses a dual-crystal transducer, with two independent crystals separated by an acoustic barrier—one for sending ultrasonic pulses and the other for receiving them.It minimizes signal clutter, and its stainless steel housing ensures durability.

Four interchangeable probes with automatic recognition

The gauge works with four types of probes: standard, micro-diameter, coarse crystal, and high-temperature. It automatically identifies the probe type and adjusts the display interface accordingly.

Switchable automatic gain

For materials with weaker ultrasonic transmission, the gauge allows users to adjust the gain, amplifying signals to ensure accurate detection and measurement.

Precision timing chip for fast, accurate readings

The device calculates material thickness based on sound velocity and echo time. The precision timing chip ensures rapid and precise measurements.

Coating penetration measurement mode

When a coating or paint layer is present, the standard probe's special mode can measure the true substrate thickness without removing the coating.

Stores up to 999 data points

Up to 999 test results can be saved and accessed anytime, minimizing data loss.

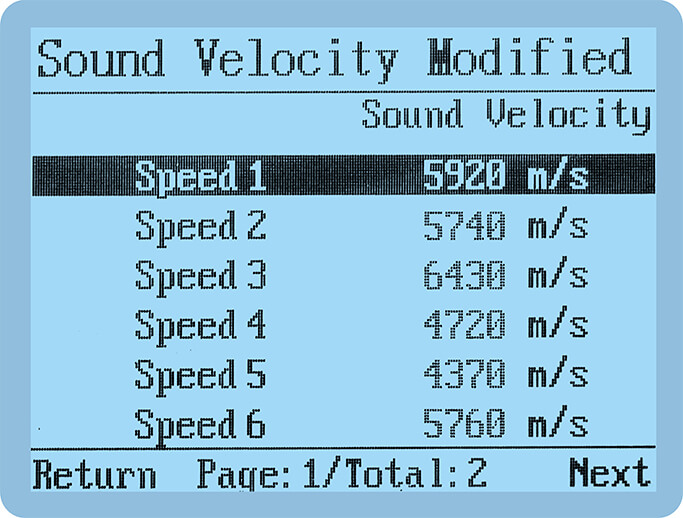

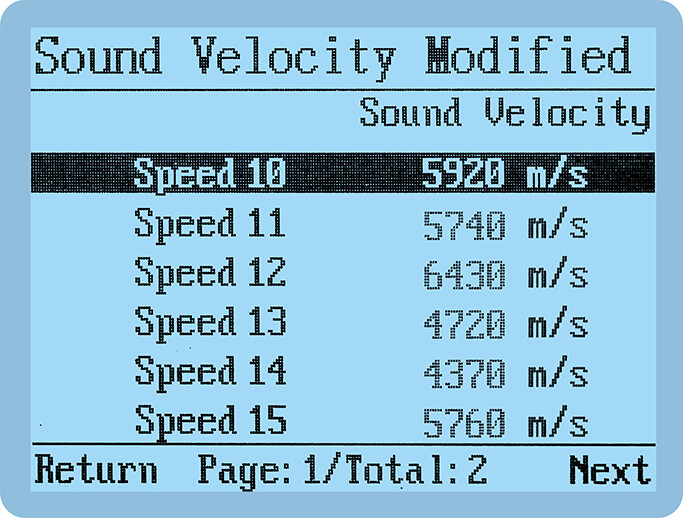

Customizable storage of 18 sound velocity settings

Users can store and modify up to 18 sound velocities (9 each in "Set by thickness" and "Manual input" modes) for more convenient thickness measurements.

Set by thickness interface

Manual input interface

Bluetooth app functionality

The built-in Bluetooth module connects to a mobile app for expanded data storage and easy sharing of measurements.

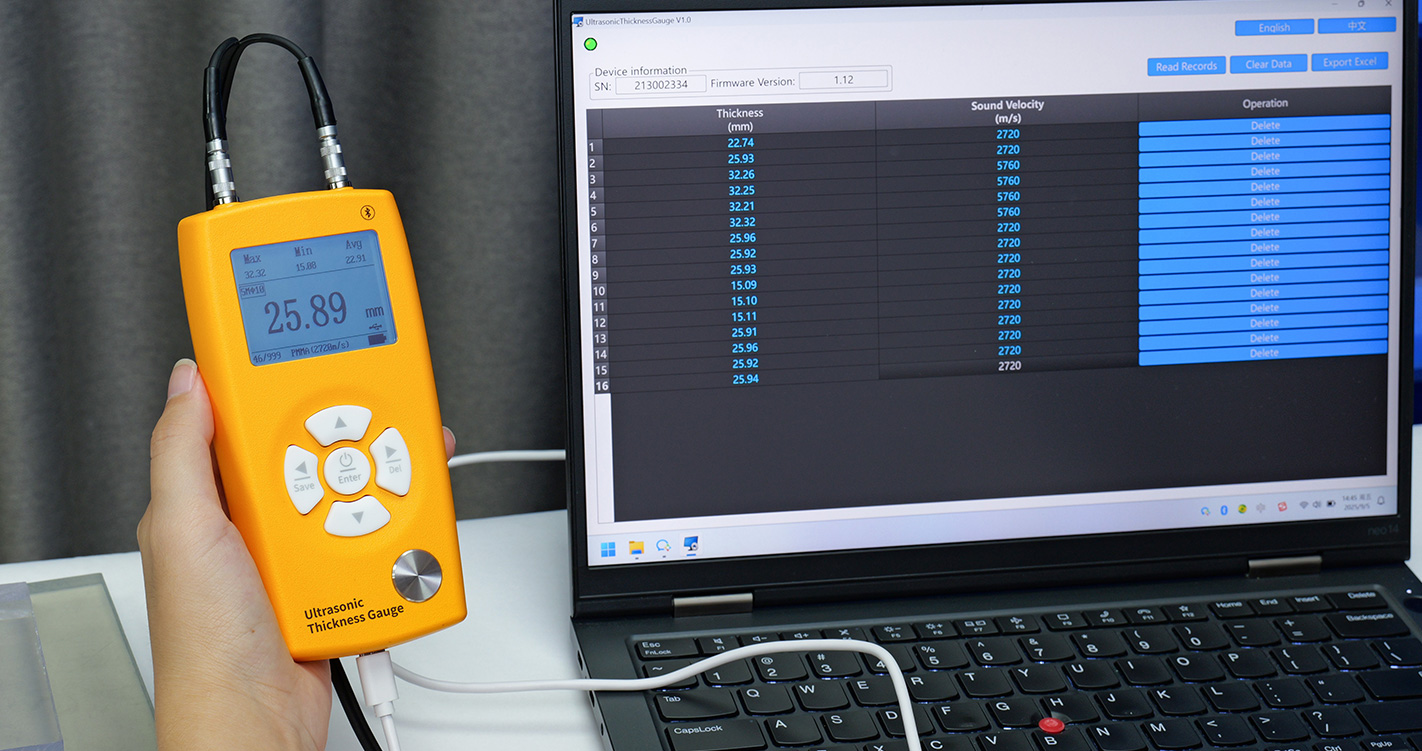

Equipped with PC Software

Equipped with PC software, the ultrasonic thickness gauge allows real-time thickness measurement and instant data export. Users can easily save and share results, improving overall work efficiency.

High accuracy and resolution

With an accuracy of ±0.05 mm and resolution of 0.01 mm (for 0.8 mm–10 mm thicknesses), the gauge meets national metrology standards.

Measures a variety of materials

Suitable for both metallic (steel, iron, aluminum, copper) and non-metallic (ceramics, plastics, glass) materials, as long as the opposing surfaces are parallel or coaxial during testing.

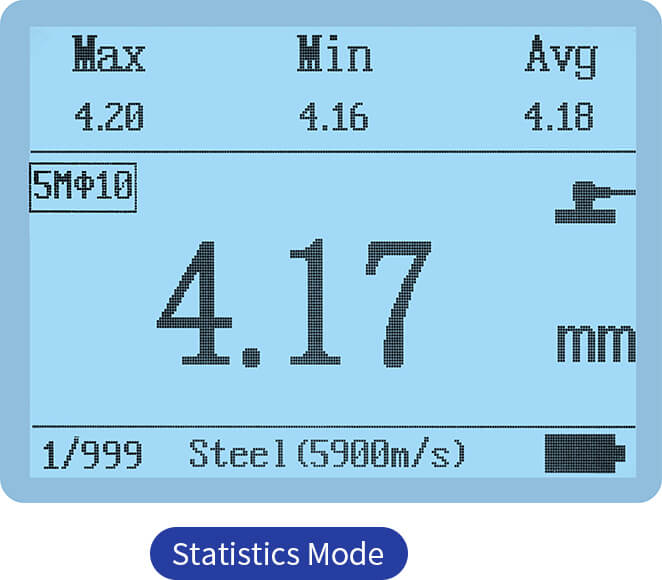

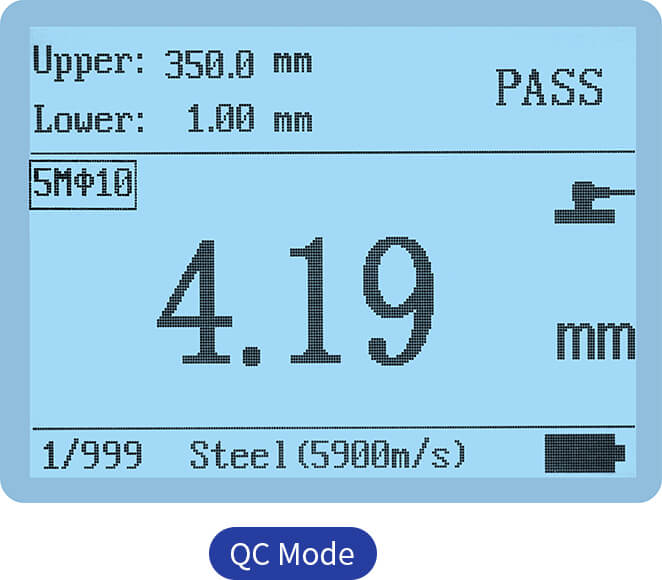

QC Mode and Statistics Mode

QC Mode lets users set upper and lower limits, providing PASS/NG alerts. Statistics Mode calculates max, min, and average values.

Preloaded sound velocities for multiple materials

The gauge includes preset sound velocities for common metals (iron, copper, aluminum) and non-metals (plastics, ceramics, plexiglass), saving users time.

Ergonomic design with non-slip silicone keys

Encased in an ABS plastic shell with non-slip silicone keys, the device offers a comfortable, secure grip.

LCD Screen offers users relaxing reading

Inch/mm switchable

Selectable display languages

Software Download

The 86212 Ultrasonic Thickness Gauge is equipped with an APP that supports Android OS version 7.0 and higher. It can be installed through the following ways:

1) Scan the QR code on the instrument with your mobile browser, follow the instructions to download and install.

2) Search for "UT and HL" (not case sensitive) in the APP Store/Google Play to install the application.